Alps Electric has developed a haptic feedback device designed to simulate touch sensation in virtual reality space, the potential applications are not limited to VR games, but also can be applied to maintenance and medical training

The Japanese company plans to begin mass production in 2017, and hope to achieve sales of 10 billion yen in 2020 (about 650 million yuan). The device will push through the motor back the user's finger to provide tactile feedback, resistance can simulate the soft and hard degree of the object. In addition, Alps Electric also by heating or a cooling element to provide temperature feedback.

Alps Electric on the development plan of this equipment is not only the existing simple technology together. To accurately display the physical object to precisely adjust the control of the software, so is located in Miyagi Prefecture of Japan's development center of software engineers need to address this challenge.

Alps Electric believes that the haptic feedback device is the core technology, and plans to set up a special department to draft the relevant patents, as well as the draft strategic cooperation with external corporate alliances

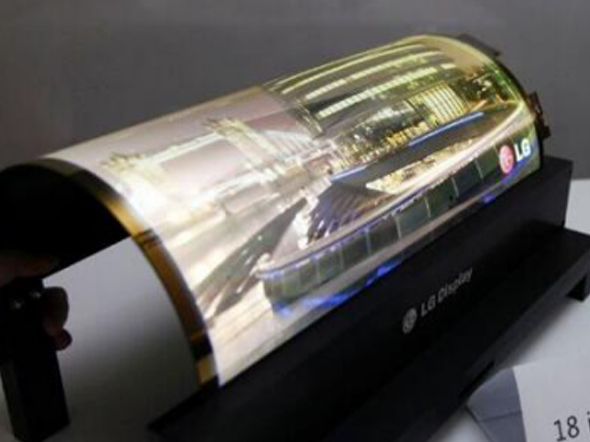

With the intelligent mobile phone, smart bracelet, TV, computer and other consumer electronic products toward the light, portable, rapid development of intelligent direction, the display screen also has a "spherical screen - flat screen - flexible screen" rapid evolution and iteration. In the spherical screen era, CRT is the only choice; in the flat screen era, LCD the King became fully deserve in the future; flexible screen era, because OLED has the advantages of simple structure, ultra light, color saturation and high contrast, low power consumption, easy to implement flexible display and other advantages, has become the industry and academia investment and research focus.

Flexible OLED panel will grow rapidly in the next 5 years

In recent years, using OLED as the intelligent mobile phone screen, smart bracelet, smart watches, TVs and other products showed rapid growth. The main battlefield in the intelligent mobile phone, more and more high-end machine using the OLED display, especially the flexible OLED screen. According to statistics, China's vivo, Meizu, OPPO and other brands began to use OLED screen intelligent mobile phone, these brands in 2016 OLED screen more than 12% penetration rate. With the Apple Corp plans in 2017~2018 will be upgraded to the LCD screen, OLED screen, the domestic and foreign industry chain are also active in the related industrial layout, the OLED market is showing a vigorous development trend. The flexible OLED display panel will maintain rapid growth the momentum in the next 5 years, the compound annual growth rate will reach more than 30%, the market scale will also be around in 2020 to more than $40 billion, OLED screen in the smartphone market. Permeability will exceed 50%.

Facing the huge market demand and bright market prospects in China, BOE, Tianma, CIGNA, and photoeloctronic, Huaxing Power, the benefit of enterprises in recent years have invested heavily in the construction of a number of G4.5~G6 generation OLED production line, 2016 has begun to have a glass of OLED display screen began to get small scale application in intelligent mobile phone based on but because our country to grasp the OLED product technology is not mature, the investment capacity of late, need to fully release around 2018. At present, the Korean enterprises in the absolute monopoly market, Samsung accounted for more than small and medium size OLED panel market share of 95%, LG is the monopoly of large size OLED TV panel market.

There are two main technical routes of OLED production

From a technical point of view, the technical route of mainstream OLED production can be divided into two types: low temperature polycrystalline silicon thin film transistor (LTPS-TFT) driving a red green blue (RGB) OLED light emitting pixels, and the oxide thin film transistor (Oxide-TFT) pixel drive white OLED light and through the filter (ColorFilter) to obtain RGB pixels. The former is mainly used for small size display, on behalf of enterprises Samsung; the latter is mainly used for large size display, on behalf of the enterprise LG.

Samsung uses LTPS technology, mainly around the small size OLED screen technology used in intelligent mobile phone force, from GalaxyS to GalaxyS7, the screen resolution is increased from 218ppi to 2K (577ppi), is expected in the future OLED mobile phone resolution may reach about 800ppi.LTPS on technical advantage in high mobility, low power consumption can be achieved, is conducive to intelligent the application of power battery in the mobile phone and other mobile terminal equipment; but the LTPS itself is a polycrystalline structure, poor uniformity, and must use the laser annealing and ion implantation process caused by the high cost, the cost of the product remains high, and difficult to be used in the production of large size panel.

LG using Oxide technology, mainly because the Oxide amorphous structure and is easy to realize large area, low preparation cost, can be used in large size OLED TV field; but the use of LG IGZO (Oxide) TFT backplane technology migration rate is low (~10cm2/Vs), leading to high power consumption, such as can greatly improve the OxideTFT the mobility, can reverse its high power consumption advantages, and is expected to gain the competitive advantage in the intelligent mobile phone such as small size of the market. Especially in the field of flexible OLED, the production of LTPS high temperature above 450 degrees, is a severe test of flexible substrate materials and manufacturing processes for high cost; and the production of Oxide the temperature can be as low as 350 DEG C, simple process, low cost, demand for raw materials is greatly reduced, is conducive to the expansion of the localization rate of raw materials and key equipment, is an effective way to achieve catch-up in China.

Packaging and bending reliability issues need to be addressed

In the high mobility of OxideTFT technology in the field of scientific research institutions, universities / China (South China University of Technology, Shanghai Univer, Fudan University, Peking University, Suzhou Institute of nano etc.) and enterprises are actively exploring new horizons. Guangzhou Photoelectric Technology Co. Ltd. (hereinafter referred to as: new horizon) is committed to break through the foreign to the IGZO Oxide material limit, is committed to development based on lanthanide doped In-Zn-O (Ln-IZO) model of Oxide semiconductor material with Nano-BarrierBCE structure process developed (5 photolithography, and s-SiTFT production line and volume), the electron mobility of high mobility OxideTFT close to 40cm2/Vs, can effectively reduce the power consumption of the OLED display. At present, new horizon is working with domestic panel makers to actively carry out cooperation, explore the high mobility of Ln-IZOTFT technology in the intelligent mobile phone and other small large size OLED display field Possibility of application.

The future development of flexible OLED display industry, in addition to the need to consider the low-cost alternative to TFT technology, but also need to consider packaging, bending and reliability issues

From the point of view of package flexible OLED devices, OLED devices in organic materials and electrode sensitive to environmental moisture, oxygen, so OLED device after completion of production must be encapsulated in situ, choke water resistance effect of oxygen, water vapor barrier packaging film capacity should reach 10-6g/m2/day in order to ensure the life of the device. The package is more effective by thin film packaging technology. The film package, not prior to the film for packaging, and then attached to the OLED device, but rather in the manufacturing of OLED electrode after the completion of the PECVD under the vacuum state, the growth of nano film has the characteristics of water oxygen barrier on OLED electrode in situ ALD method in order to achieve the purpose, packaging, technical requirements are very high. Especially for flexible OLED, because of the need to face free bending of the package performance will inevitably put forward more stringent requirements.

From the angle of bending properties of flexible OLED display screen, now on the market of flexible OLED is all fixed surface, the user can not according to the preferences of free folding of their own, mainly because the flexible OLED display the number of bends or bending radius exceeds a certain limit, it will appear the problem of aging device, resulting in decreased brightness, the dark spots, dark line damage, the service life of the rapid recession. This needs from the perspective of "material - thin film devices - technology", solve continuously through the system research.

In short, flexible OLED display industry is in a period of rapid development, the industry has a bright future. But China's industrial development is still facing lack of accumulation of technology, production line construction started late, the problem of equipment and materials imported. This requires matching between the domestic downstream industries closely, strive for the initiative in the new round of flexible OLED competition in the industry.